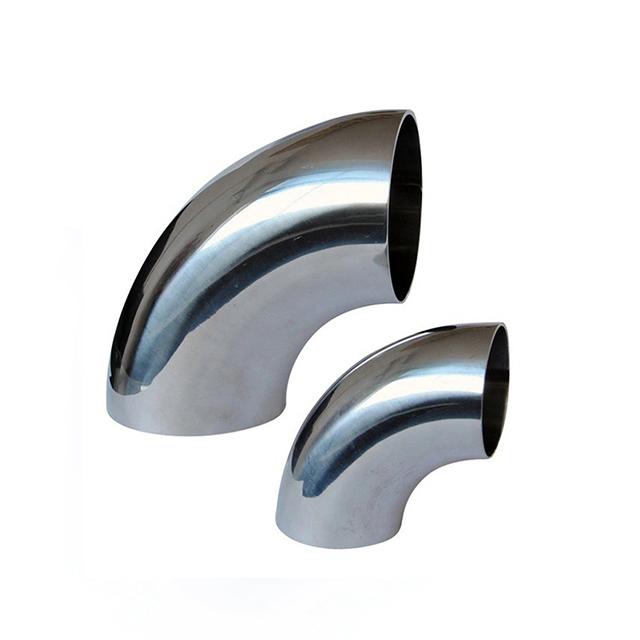

Specifications of sanitary stainless steel pipe fittings and the application and differences of carbon steel pipes

Design Basis

1. Comparison between Sanitary Stainless Steel Pipe Fittings and carbon steel

First, let's look at the main differences between ordinary carbon steel and stainless steel.

2. Stress/Strain Graph

The linear portion of the stress/strain curve for carbon steel is actually a straight line to the yield point, while the linear area for stainless steel is about 50% of 0.2.

When the stress level is in the inelastic region, the bending design theory and Hooke's law used in structural design, that is, stress and strain are proportional, do not really apply to stainless steel.

Therefore, it is relatively simple to design stainless steel component structures under low stress levels, but it is necessary to consult the standards for deformation and local bending under high stress levels.

3. Tension

In modern structural regulations, the tensile stress plus the load factor is linked to the yield stress of the material of the gross section, and the ratio of the tensile ultimate strength to the yield stress is used to verify the net section.

The ratio of the tensile ultimate strength to the yield stress of stainless steel is 2.4, while the range for carbon steel is 1.6 to 2.1.

Tensile components need to undergo two strength checks:

① Yield stress of gross section

② Ultimate tensile strength of net effective section (maximum 1.2)